YiFan Conveyor - Conveyor Manufacturer and One-Stop Solution Service Provider for Truck Loading Conveyor and Flexible Roller Conveyor System.

What Are Conveyors Used In Textile Industry?

When you think about the textile industry, images of colorful fabrics, spinning wheels, and sewing machines might dance through your mind. But there's an unsung hero in the background, quietly making everything tick: conveyor systems. These are the lifelines that move materials from point A to B, ensuring that the beautiful garments you love make it from concept to closet without a hitch.

Let's dive into the world of conveyors in the textile industry, uncovering their pivotal role in enhancing efficiency and productivity. It's a journey through the backbone of textile manufacturing, where innovation meets tradition to weave the very fabric of our daily lives.

Types Of Conveyors Used In The Textile Industry

Conveyors are the workhorses of the textile world, each type serving a unique purpose to streamline processes.

Belt Conveyors: The Lifeline for Moving Materials

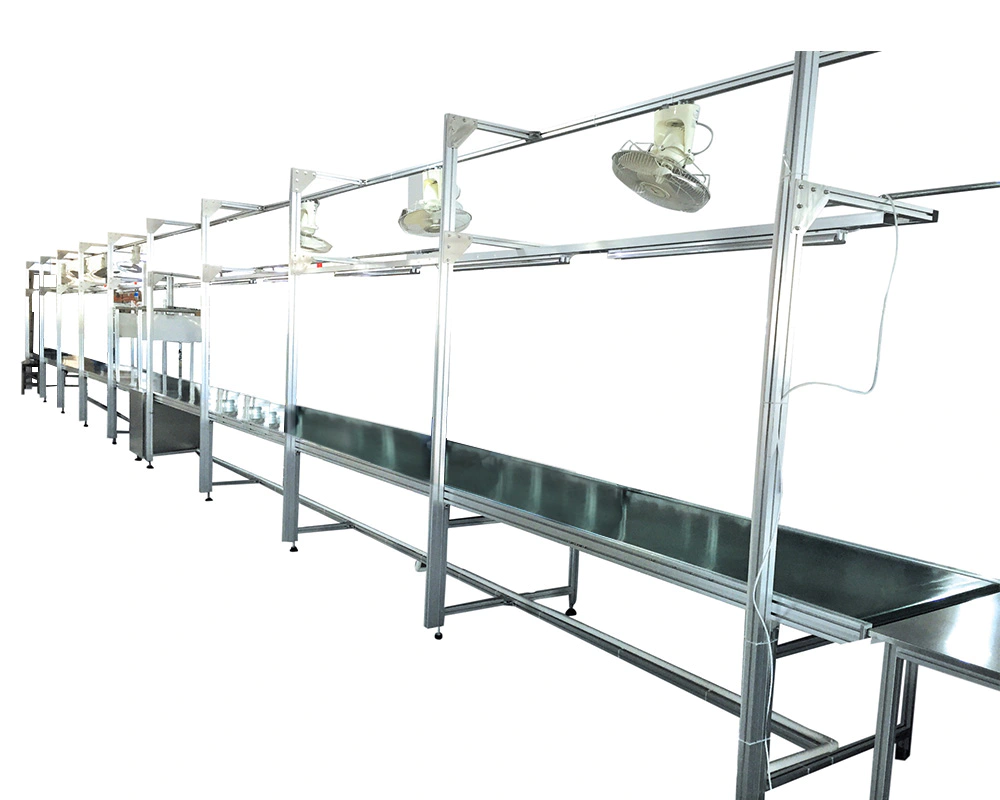

Belt conveyors are perhaps the most well-known and versatile types used across various industries, including textiles. They consist of a continuous belt made of a sturdy material that loops over two or more pulleys.

In the textile industry, they’re the go-to for moving raw materials like cotton, wool, or synthetic fibers from one point to another. Whether it’s transporting these materials to processing machines or moving finished products to the packaging area, belt conveyors do the job with efficiency and ease.

Their simplicity, combined with the ability to handle a range of materials from light to heavy, makes them indispensable.

Roller Conveyors: Ideal for Heavy Fabric Rolls

Roller conveyors are designed with a series of rollers mounted in a frame, which can be powered or unpowered (gravity-driven). They shine in scenarios where heavy items need to be moved effortlessly across a flat or slightly inclined plane. In the textile industry, roller conveyors are perfect for transporting large and heavy rolls of fabric.

The beauty of roller conveyors lies in their ability to facilitate the movement of these bulky items with minimal effort, protecting the fabric from damage while ensuring that production lines keep moving smoothly.

Modular Conveyors: Flexible Configurations for Diverse Operations

Modular conveyors are the chameleons of the conveyor world. Comprised of interchangeable sections, they can be configured and reconfigured to suit the changing needs of a textile operation.

This adaptability makes them especially valuable in an industry where production requirements can shift rapidly. Modular conveyors can handle a wide range of materials and are ideal for scenarios where space is at a premium, or the production line needs to be frequently adjusted for different processes or products.

Pneumatic Conveyors: For Delicate and Lightweight Textile Products

Pneumatic conveyors use a system of tubes and compressed air to move materials from one place to another. They are particularly useful for handling delicate or lightweight textile products that might be damaged by more traditional conveying methods. These conveyors can gently and quickly transport items like small fabric cuts, yarn, or finished garments through the production area.

The lack of mechanical parts in contact with the textile materials reduces the risk of damage, making pneumatic conveyors an excellent choice for quality-sensitive operations.

Choosing The Right Conveyor: Factors To Consider

Choosing the right conveyor system for your textile operation is crucial to enhancing efficiency, ensuring product quality, and optimizing your production line. It's not just about picking a conveyor; it's about finding the perfect fit for your specific needs.

Let's break down the key factors you should consider when selecting a conveyor for the textile industry.

Material Handling Requirements

First and foremost, consider what you're moving. The weight, size, and nature of the textile materials or products you need to transport play a pivotal role in determining the type of conveyor that's best suited to your needs.

Light, delicate items like fabric-cuts or finished garments may require a different approach, such as pneumatic conveyors, to prevent damage. Conversely, heavy rolls of fabric might be better suited to roller conveyors, which can handle their weight more effectively.

Space Constraints

Space is a premium commodity in any manufacturing setting, and the textile industry is no exception. The layout of your facility can greatly influence the type of conveyor system that will work best for you.

Modular conveyors offer flexibility and can be configured to fit into tight spaces or navigate around obstacles. If your operation is spread over a large area, long belt conveyors might be the solution to move materials efficiently across distances.

Efficiency and Speed

In the fast-paced world of textile manufacturing, time is of the essence. The efficiency and speed of your conveyor system can have a significant impact on your overall productivity.

Consider the pace at which your conveyor needs to operate to keep up with production demands. High-speed conveyors can increase throughput but may require more sophisticated controls to handle delicate materials safely.

Applications Of Conveyors In Textiles

Conveyors play a pivotal role in the textile industry, streamlining every phase of production from the initial handling of raw materials to the final stages of packaging and distribution. Their applications are as diverse as the industry itself, touching on everything from the movement of bulky raw materials to the delicate handling of finished garments.

Let's explore how conveyors are integrated into various stages of textile production, demonstrating their versatility and critical importance in ensuring efficiency, quality, and speed in operations.

Handling Raw Materials

The journey of a textile product begins with raw materials such as cotton, wool, synthetics, and other fibers. Conveyors are instrumental in moving these materials through initial processing stages like cleaning, carding, and combing.

Belt conveyors, for instance, efficiently transport bales of cotton to carding machines, where the fibers are aligned. This initial integration of conveyors helps in maintaining a steady flow of materials, ensuring that the processing machinery is continuously fed without delays, thus optimizing the production line's efficiency from the very start.

Processing and Weaving

Once the fibers are prepared, they move on to spinning, weaving, and knitting sections of the production line, where they are transformed into fabrics. Here, conveyors facilitate the smooth transition of fibers into yarns and then fabrics. Modular conveyors offer the flexibility needed to accommodate the diverse processes and machinery involved in this stage.

They can be easily reconfigured to suit the layout of spinning frames and looms, ensuring that materials move seamlessly from one process to the next. This not only enhances efficiency but also helps in maintaining the quality of the textiles by minimizing handling errors and damage.

Dyeing, Printing, and Finishing

After weaving, textiles undergo various finishing processes, including dyeing, printing, and adding special finishes that enhance their appearance, texture, and durability. Conveyors play a crucial role in moving textiles through these chemical and mechanical processes.

Pneumatic conveyors, for instance, are particularly useful in moving delicate fabrics between dye vats and drying areas, minimizing physical contact and thus preserving the quality of the delicate fabric surfaces. The precise control offered by these conveyors ensures that each piece of fabric receives uniform treatment, crucial for maintaining consistent quality across batches.

Automated Sorting and Packaging

In the final stages of production, conveyors streamline the sorting, folding, and packaging of textiles, preparing them for distribution. Automated conveyor systems equipped with sensors and sorting mechanisms can classify textiles based on size, color, or type, directing them to appropriate packaging stations.

This automation significantly reduces manual labor, speeds up the packaging process, and minimizes errors, ensuring that products are market-ready in the shortest possible time.

Warehouse Management

Beyond production, conveyors are integral to efficient warehouse management in the textile industry. They facilitate the organized storage and retrieval of raw materials and finished goods, optimizing space utilization and improving inventory management.

Roller conveyors, for example, are used for moving heavy crates of textiles within the warehouse, while belt conveyors can transport items to and from storage racks. This efficient movement of goods minimizes the time spent on loading and unloading, enhancing overall operational efficiency.

Conclusion

Conveyors in the textile industry are more than just machines; they are the threads that connect every stage of production, weaving efficiency and productivity into the very fabric of the industry.

As we look to the future, the evolution of conveyor technology promises to keep pace with the industry's needs, ensuring that textiles continue to play a central role in our lives. The journey of conveyors is a testament to innovation, a story of how tradition and technology can come together to create something truly remarkable.

Get in touch with us

QUICK LINKS

PRODUCTS

CONTACT US

E-Mail : sales01@yfconveyor.com

24 Hour Hotline : +86 13958241004

Add: No.77,Heyi Road,Gulou Street,Haihu,Ningbo China