YiFan Conveyor - Conveyor Manufacturer and One-Stop Solution Service Provider for Truck Loading Conveyor and Flexible Roller Conveyor System.

The Working Principle Of Belt Conveyors

Belt conveyors are the unsung heroes of the material handling world. These workhorses of numerous industries move goods and materials of all shapes and sizes from one point to another with efficiency and ease. But how exactly do they work? Stick around, because we're about to unpack everything you need to know about the working principle of belt conveyors.

From their components to their vast applications, we've got you covered.

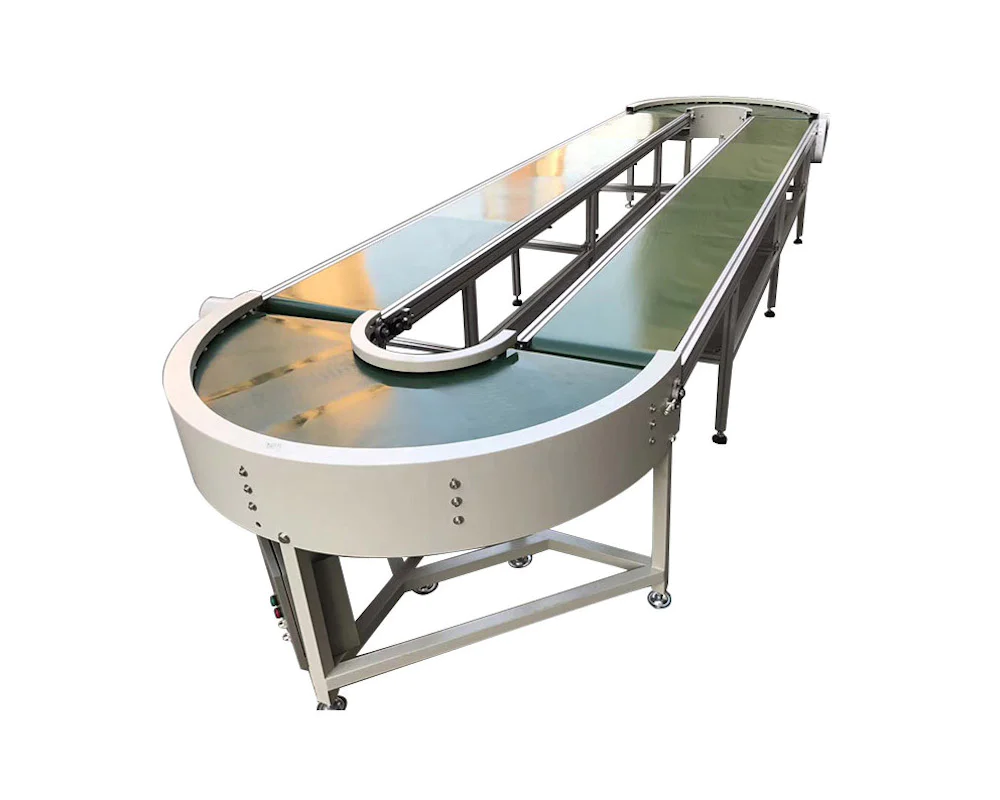

When we talk about belt conveyors, we're diving into a world of essential engineering marvels. At their core, belt conveyors consist of a belt, pulleys, rollers, and a frame that together create a seamless path for transporting materials.

The beauty of these systems lies in their simplicity and efficiency. Whether it's a flat belt conveyor moving boxes in a warehouse or a modular belt conveyor sorting packages, each type plays a pivotal role in industry operations.

The Working Principle Of Belt Conveyors

The magic of belt conveyors lies in their simplicity. The heart of the system is the drive mechanism, which uses a motor to turn the drive pulley, moving the belt and anything on it with ease. But it's not just about moving; it's about moving smartly. The design ensures materials stay in place without slipping off the belt, thanks to the clever use of friction and belt tension.

The Role of the Drive Mechanism

At the heart of every belt conveyor is a powerful drive mechanism. It transforms electrical energy into mechanical energy, powering the drive pulley to move the belt and its cargo. This setup is the pulse of the operation, dictating the speed and efficiency of the conveyor. The drive mechanism is a testament to the ingenuity of engineers, optimizing the transfer of power for maximum productivity.

Movement of Materials

The principle of friction between the belt and materials is what keeps the conveyor moving smoothly. The belt's surface, material, and tension are designed to ensure materials move steadily and securely. Whether it's heavy mining materials or delicate packages, the conveyor belt handles them with care, proving that even the toughest jobs can be done with precision and grace.

Key Components

Every component of a belt conveyor plays a crucial role in its operation. The conveyor belt itself is a marvel of material engineering, designed to withstand wear and tear while moving goods efficiently.

Pulleys and rollers support the belt, guiding it smoothly along its path. The choice of materials and designs for these components directly impacts the performance and longevity of the conveyor system.

Conveyor Belts

Conveyor belts are not one-size-fits-all. They come in various materials and designs, each selected to suit the specific demands of the operation. From rubber to PVC, or even metal, the right belt material ensures efficiency and durability.

This is where the science of material handling meets the art of engineering, creating solutions that move the world forward.

Pulleys and Rollers

Pulleys and rollers are the guiding stars of belt conveyors. They ensure the belt moves smoothly and remains aligned, preventing slips and reducing wear. The design and material of these components are critical, affecting everything from the conveyor's speed to its noise levels. It's a balance of engineering precision and practical design, ensuring long-term performance and reliability.

Advanced Features And Technologies

As technology advances, so do belt conveyors. Let’s break down the advanced features and technologies of belt conveyors into clear, concise bullets:

● Automated Conveyor Systems: Incorporates sensors and control systems to automate material handling, reducing manual intervention and increasing efficiency.

● Smart Conveyors with IoT Integration: Utilizes Internet of Things (IoT) devices to monitor conveyor performance, predict maintenance needs, and optimize operations.

● Energy-Efficient Technologies: Features designs and components aimed at reducing energy consumption.

● braking systems that recapture energy.

● Modular and Scalable Designs: Offers flexibility to easily expand or modify conveyor systems as business needs change.

● Precision Material Handling: Advanced control systems allow for precise handling of materials, improving process control and reducing waste.

● Integrated Sorting Systems: Incorporates sorting mechanisms directly into the conveyor system, streamlining operations and reducing the need for separate processes.

Applications Of Belt Conveyors

Belt conveyors are versatile systems used across a broad range of industries for the efficient transport of materials. Let's explore their applications in detail, showcasing just how indispensable they are in today’s industrial landscape.

Manufacturing

In the manufacturing sector, belt conveyors play a crucial role in assembly lines, transporting parts and products through various stages of production. They streamline processes, from the initial assembly to the final product packaging, enhancing efficiency and productivity.

● Moving components between assembly stations.

● Feeding parts into processing machines.

Warehousing and Distribution

Belt conveyors are key to the operations of warehouses and distribution centers, facilitating the movement of goods for storage, order picking, and shipment preparation. They help in managing inventory and ensure the quick, safe handling of products.

● Sorting and routing items for shipping and receiving.

● Transferring goods between different warehouse areas.

Food Processing

In the food industry, conveyors are used for transporting raw ingredients, processing foods, and packaging finished products. They are designed to meet strict hygiene standards, preventing contamination and ensuring food safety.

● Conveying products through cooking, cooling, and freezing processes.

● Moving packaged food for inspection and packaging.

Mining

The mining industry relies on belt conveyors for the efficient transport of materials extracted from the earth, such as coal, minerals, and ores. These heavy-duty conveyors are built to withstand harsh environments and move large volumes of material.

● Transporting ore from the mine to processing facilities.

● Handling bulk materials and aggregates.

Conclusion

The working principle of belt conveyors is a testament to human ingenuity and engineering. From their basic components to advanced technologies, belt conveyors have stood the test of time, proving their worth in countless industries.

As we move forward, the evolution of conveyor technology promises to make these systems even more efficient, sustainable, and integral to our world. So, next time you see a conveyor belt in action, take a moment to appreciate the complex simplicity and essential role it plays in keeping our world moving.

Get in touch with us

QUICK LINKS

PRODUCTS

CONTACT US

E-Mail : sales01@yfconveyor.com

24 Hour Hotline : +86 13958241004

Add: No.77,Heyi Road,Gulou Street,Haihu,Ningbo China