YiFan Conveyor - Conveyor Manufacturer and One-Stop Solution Service Provider for Truck Loading Conveyor and Flexible Roller Conveyor System.

How Conveyor Systems Revolutionize The Tobacco Industry

You might not think about it, but the tobacco industry is a whirlwind of activity, constantly evolving and innovating. And at the heart of this transformation? Conveyor systems. These aren't your average belts and rollers; they're the unsung heroes making sure your favorite tobacco products are produced efficiently, safely, and consistently.

Conveyor systems in the tobacco industry are more than just a means of transport; they're a critical component in the manufacturing process. From the moment raw tobacco leaves enter a facility, they're on a conveyor-led journey, undergoing various processes until they emerge as the final product. It's an intricate dance of machinery and technology, all working together seamlessly.

The Anatomy Of Conveyor Systems In Tobacco Manufacturing

As we explore the anatomy of conveyor systems, it's fascinating to see how they're tailored to meet the unique demands of tobacco manufacturing. Let's delve into the different types of conveyor systems used, each with its role in transforming raw tobacco into a quality product.

Types of Conveyor Systems Used

In the intricate world of tobacco manufacturing, various types of conveyor systems are employed, each serving a unique purpose. Understanding these types is key to appreciating how they streamline the production process. Here are the main types used:

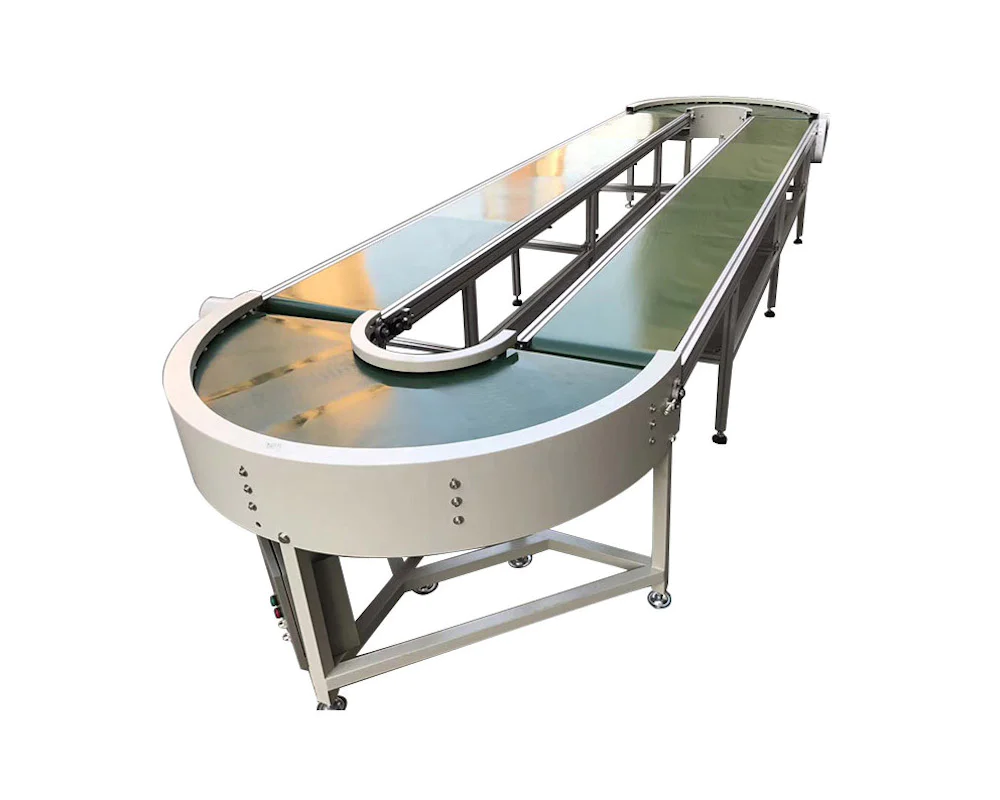

● Belt Conveyors: The most common and versatile type, belt conveyors consist of continuous belts running over pulleys. They are ideal for transporting a wide range of tobacco products, from loose leaves to packed cartons. Their simplicity and effectiveness make them a staple in the industry.

● Roller Conveyors: These consist of rollers arranged in parallel, offering a surface ideal for moving bulky or heavy tobacco products. Roller conveyors are particularly useful in areas where products need to be accumulated or diverted to different areas of the factory.

● Pneumatic Conveyors: Utilizing air pressure or vacuum, pneumatic conveyors transport tobacco products through tubes. They are perfect for moving fine tobacco particles or powders, ensuring that even the smallest product components are handled gently and efficiently.

● Vibratory Conveyors: These systems use vibration to move tobacco. They are particularly useful for sorting or separating tobacco leaves based on size or weight, ensuring uniformity and quality in the final product.

● Flexible Conveyors: As their name suggests, these conveyors are adaptable and can be maneuvered around obstacles in the factory. They are ideal for facilities where space is limited or where the layout requires a more dynamic approach to material handling.

Key Components and Their Functions

Understanding the key components of conveyor systems and their functions is crucial in appreciating how they optimize tobacco production. Each component plays a vital role in ensuring the conveyor system runs smoothly and efficiently. Let's delve into these components:

● Conveyor Belts: The heart of the belt conveyor system. Made from various materials like rubber, PVC, or fabric, these belts transport tobacco products from one point to another. They come in different textures and strengths, tailored to handle various types of tobacco products without causing damage or loss.

● Motors and Drives: These are the power sources that set the conveyor belts in motion. Motors and drives control the speed and torque, ensuring that the conveyor runs at the optimal pace for the specific stage of tobacco processing. Precise control of these elements is key to maintaining efficiency and productivity.

● Sensors and Controllers: Acting as the conveyor system's brain, sensors and controllers manage and monitor the conveyor's operation. They detect and respond to conditions like belt speed, product weight, and system malfunctions. This technology allows for real-time adjustments, ensuring smooth operation and reducing downtime.

● Pulleys and Rollers: These components support and guide the conveyor belt. Pulleys, typically located at the ends of the conveyor, facilitate the belt's movement, while rollers provide support along its length. They play a critical role in maintaining the belt's tension and alignment, crucial for efficient operation.

● Loading and Discharge Points: Where the product enters and exits the conveyor. These points are designed for efficient transfer of tobacco products, minimizing spillage and ensuring a smooth transition between different stages of the production process.

● Frame and Structure: The backbone of the conveyor system, providing support and stability. The frame and structure must be robust enough to handle the load and the rigors of the production environment. They are often designed with adaptability in mind, allowing for adjustments and expansions as production needs change.

The Journey Of Tobacco On Conveyor Belts

Let's take a closer look at the journey of tobacco on these conveyor belts, a crucial pathway from nature to the final product. Starting with raw leaves, we'll follow their transformation into the processed tobacco that's familiar to consumers around the world.

From Raw Leaves to Processed Tobacco

Picture this: a leaf of tobacco starting its journey. It's first sorted and handled on conveyors, chosen for its quality. Then, it's off to drying and curing, where conveyors move it through controlled environments to develop its flavors.

Next comes cutting and conditioning, where the leaves are prepared for their final form. Throughout this process, conveyors are the silent guides, ensuring each leaf is treated with precision.

Packaging and Distribution

Once processed, it's time for packaging. Here, conveyors work hand-in-hand with robotic systems, creating an assembly line that's a marvel of modern manufacturing. The packaged products are then whisked away on conveyors, ready for distribution. It's a symphony of movement, each step carefully choreographed for maximum efficiency.

Advantages Of Conveyor Systems In Tobacco Production

Diving into the world of tobacco production, the role of conveyor systems is nothing short of transformative. These ingenious systems bring a host of advantages to the table, elevating the entire manufacturing process to new heights. Let's unpack these benefits:

● Increased Efficiency and Productivity: Conveyor systems are the unsung heroes when it comes to boosting productivity. They move tobacco through the production line at a consistent pace, eliminating bottlenecks and downtime. This streamlined process means more tobacco is processed in less time, translating into higher output and increased efficiency.

● Enhanced Quality Control: Quality is paramount in tobacco production, and conveyor systems play a pivotal role in ensuring it. These systems provide a controlled environment where tobacco is handled and processed with precision. Automated quality checks can be integrated along the conveyor belt, ensuring that each product meets the high standards expected by consumers.

● Cost-Effectiveness: By automating significant parts of the production process, conveyor systems reduce the need for manual labor. This not only cuts down labor costs but also minimizes human error, leading to a more cost-effective operation. In the long run, the investment in conveyor technology pays off through increased productivity and reduced overheads.

● Safety and Compliance: In an industry that's heavily regulated, maintaining safety and compliance is crucial. Conveyor systems contribute to a safer working environment by reducing direct handling of tobacco, thereby minimizing health risks to workers. Additionally, these systems can be designed to comply with industry regulations, ensuring that the manufacturing process adheres to the necessary standards.

● Scalability and Flexibility: As the demands of the tobacco industry evolve, conveyor systems offer the flexibility and scalability needed to keep up. They can be easily modified or expanded to accommodate new products, changes in production volume, or advancements in technology. This adaptability makes conveyor systems a long-term asset in the ever-changing landscape of tobacco production.

Conclusion: The Transformative Impact of Conveyor Systems

In closing, conveyor systems in the tobacco industry are more than just machinery; they're a testament to human ingenuity and the relentless pursuit of efficiency and quality. They've transformed the industry, making it what it is today – a high-tech, high-efficiency powerhouse.

Get in touch with us

QUICK LINKS

PRODUCTS

CONTACT US

E-Mail : sales01@yfconveyor.com

24 Hour Hotline : +86 13958241004

Add: No.77,Heyi Road,Gulou Street,Haihu,Ningbo China