YiFan Conveyor - Conveyor Manufacturer and One-Stop Solution Service Provider for Truck Loading Conveyor and Flexible Roller Conveyor System.

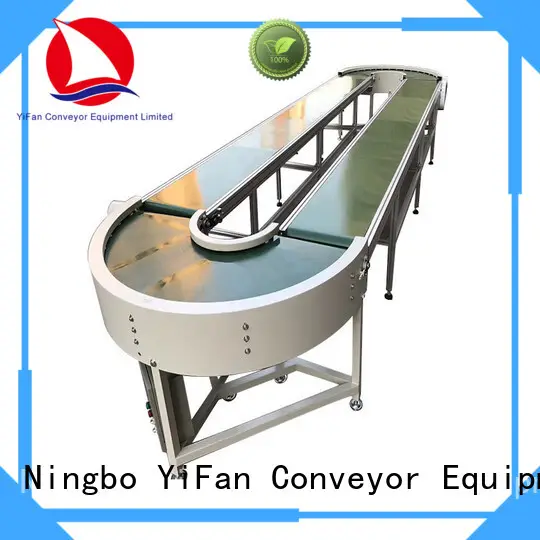

china manufacturing conveyor system heavy for food industry

1. For its material, we used curve belt conveyor that was typical for conveyor system because it is corrugated sidewall conveyor belt .

2. The service life of product far exceeds the industry average.

3. Because of the features of curve belt conveyor , conveyor system becomes most people's choice.

4. Ningbo YiFan Conveyor Equipment Co.,Ltd has advanced processing technology, exquisite craftsmanship, and strict quality control system.

5. Ningbo YiFan Conveyor Equipment Co.,Ltd is a professional company which produces different types of conveyor system .

Company Features

1. High-quality conveyor system is one of the reason that makes YiFan prosperous.

2. We have a professional product development team. They have much expertise in improving product performance. They effectively coordinate and implement our production with their innovative ideas.

3. Unswervingly implementing the strategy of strengthening belt conveyor proves to be very essential. Get price! Ningbo YiFan Conveyor Equipment Co.,Ltd exists to bring our customers best rubber conveyor belt manufacturers and considerate service. Get price! With the goal of becoming stronger in the future, YiFan aims to provide the best conveyor belt suppliers and service for customers. Get price! YiFan always pursues the coordinated and win-win situation with customers. Get price!

BINCEN·Weighing Batching System

Introduction

FS3198-C3x,C4x,C5x,C6x controllers have 3~6 weighing and batching channels, the batching system requires no PLC or computer control. These weighing and batching controllers are made by our company which summarize the years experiences of electronic weighing scale in developing and applying methods, adopt single chip MCU, low drift differential amplifier, high accuracy A/D, consecutive filter in quasi-stationary dynamic weighing. The feeding channel control is running with automatic tare at first, and channel feeding control by net weight. It amends arriving advance weight when each channel feeds in end, and feeds tinily repeatedly till weight qualified if less than qualified weight. The total weight is displayed till all channels feeding end. The instruments use menus for batching administrator prescription input, work prescription input and advanced control parameters input with password protection. The system control actuators may be tested directly by instrument panel at manual mode. They process unload end control with small weight threshold and time delay. The weighing and batching control may be set up as times mode or continuous mode.

FS3198-C31,C41,C5,C6 use single speed feeding-in control. FS3198-C49 uses double speeds feeding-in control. The FS3198-C41,C49 four channels batching meter has automatic vibrating control when channel feeding-in or scale unloading at running.

FS3198-C3~C6 weighing and batching controllers are used in batch scale or weighing batch, multichannel with quantitative control on the weighing scale needed no PLC or industrial computer.The system control actuators may be tested directly by instrument panel at manual mode. Under the manual mode, the automatic control logic is of no effect, and you can use the numeric keys to test the work states of the relay-board’s outputs. This function is convenient for debugging and maintenance of weighing control system.

Weighing&Batching Types (FS3198-C31,FS3198-C41, FS3198-C48,FS3198-C49, FS3198-C52,FS3198-C62)

Main features

• 1~8 pieces of analog loadcells of strain gauge type.

• static accuracy: OIML Ⅲ, n=3000

• dynamic accuracy: ±0.2~2% due to specific loadcells, actuators and material flow rate.

• adopt 7 figures, display 10LED, 24 keys to get intuitive and convenient operation, easy adjustment and maintenance.

• 3~6 kinds of materials , one or two feeding speed control.

• RS232 interface port printing results connecting serial port printer.

• running by times or continuously.

• control output is OC logic output or relays type.

• suitable for weighing and batching scale, gravimetric filling scale, quantitative filling scale, weighted threshold scale, etc.

• power source selectable : DC8~15V/1~2A,AC9~18V/1~2A,AC220V/50Hz/15~30VA

Common feeding or unloading Actuator:

cylinder drive door; screw, belt, electric vibration, electromagnetic valve, pump,etc.

Centralized-Control Panel Types: ·

· 1 aggregate scale + 1 or 2 cement scales;

· 1 aggregate scale + 1 cement scales + 1 water scale;

· 1 aggregate scale + 1 cement scale + 1 water scale + 1 admixture scale, etc.

APPLICATIONS:

• Packing scale or machine

• Filling scale or machine

• Simple weighing and batching scale

• Hopper control scale

• Tank, bucket container scale,etc.

Weighing&Batching Types and Main Functions Table

(FS3198-C31,FS3198-C41, FS3198-C48FS3198-C49, FS3198-C52,FS3198-C62)

FS3198-C4m Four Weighing Threshold Controller

The FS3198-C4m weighing threshold controller, can be applied to mix the material scale, weighing system or definite quantity control weighing system and so on. Because FS3198-C4m controller’s threshold control function is powerful, the definite quantity weighing control scale, such as simple weighing and batching scale or hopper scale, tanker scale, can be built without the PLC or industry computer to get to be more compact, stable and reliable, simple and convenient operation, and easy to maintain.

Under the manual mode, the automatic control logic is of no effect, and you can use the numeric keys to test the work states of the relay-board’s outputs. This function is convenient for debugging and maintenance of weighing control system.

Scheme of independent gross weight threshold control mode:

GW<1C: K1_ON #1( light on), GW>=1C: K1_OFF #(light off)

GW<2C: K2_ON #2(light on), GW>=2C: K2_OFF #(light off)

GW<3C: K3_ON #3(light on), GW>=3C: K3_OFF #(light off)

GW<4C: K4_ON #4(light on), GW>=4C: K4_OFF #(light off)

NOTE: Threshold values ← 1C~4C, Gross Weight ← GW , four relay outputs ← K1~K5 FS3198-C4m

Scheme of gross weight interval threshold control mode:

GW<1C: K1_ON #1( light on), GW>=1C: K1_OFF #(light off)

GW<2C: K2_ON #2(light on), GW>=2C: K2_OFF #(light off)

GW<3C: K3_ON #3(light on), GW>=3C: K3_OFF #(light off)

GW<4C: K4_ON #4(light on), GW>=4C: K4_OFF #(light off)

Main features

• 1~6 pieces of analog loadcells of strain gauge type.

• Static accuracy: OIML Ⅲ, n=3000

• Adopt 7 figures, display 10LED, 24 keys to get intuitive and convenient operation, easy adjustment and maintenance.

• Control output is OC logic output or relays type.

• Power source selectable : DC8~15V/1~2A,AC9~18V/1~2A,AC220V/50Hz/15~30VA

APPLICATIONS:

• Packing scale or machine

• Filling scale or machine

• Simple weighing and bathing scale

• Hopper control scale

• Tank, bucket container scale,etc.

Examples of Questions below:

1.As to aggregate weighing,which position should the electronic scale be finished at?

2.As to cement scale,is put on mixer?

3.Water,admixture: are they at weighing control or timing feeding control?

4.Mixer Run/Stop control is focus on control room or followed by the mixer which has been equipped with control panel?

5.Discharging of cement scale is controlled by pneumatic door way?If yes,you need air compressor Run/Stop to control by button.

6.The mixing and discharging time are controller by artificial manual control?or automatically control?As you mention,the admixture,water need to be controlled automatically.

Other question:Each actuator’s working voltage,motor power is?

QUICK LINKS

PRODUCTS

CONTACT US

E-Mail : sales01@yfconveyor.com

24 Hour Hotline : +86 13958241004

Add: No.77,Heyi Road,Gulou Street,Haihu,Ningbo China